UL 508 Control Panels

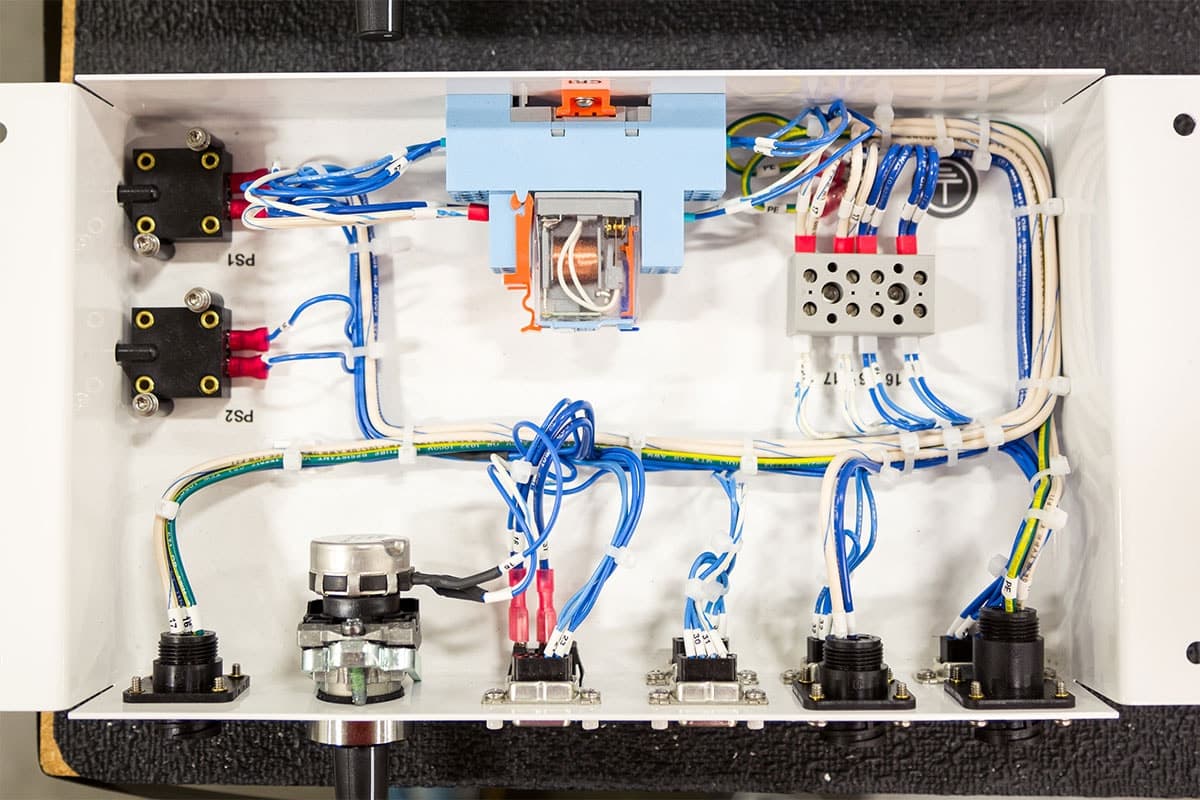

UL 508 control panels, system integration & contract builds: custom-built, UL-certified, and cleanly manufactured at Prairie Electric.

Behind the scenes, right at the heart of your operation.

At Prairie Electric, our Control Panel Division does more than build high-quality enclosures—it builds relationships. With a focus on both certified UL 508 industrial control panels and non-UL electro-mechanical assemblies for complex applications, our panel shop is the quiet powerhouse behind some of the Pacific Northwest’s most demanding industries.

Operating just under 40 strong, this specialized division merges engineering, fabrication, and systems integration under one roof: giving OEMs, manufacturers, and production engineers clean, reliable, and customizable control panel solutions that move seamlessly from idea to implementation.

Whether you’re delivering smart car washes, future-facing data centers, or food production lines under FDA regulation, Prairie Electric designs and builds to meet strict technical standards, tight deadlines, and the unexpected chaos that often defines your world.

What We Build and How We Work

Prairie Electric’s Control Panel Division is structured around two primary functions:

UL 508 Certified Industrial Control Panels

These panels are engineered to safely operate motors, sensors, conveyors, pumps, fans, and other industrial systems—faithfully built to the UL 508 standard and rigorously tested. You’ll find them in facilities ranging from food processing plants to semiconductor fabs.

These aren’t off-the-shelf boxes tossed into production—they’re engineered assemblies with custom layouts, PLCs, VFDs, status lights, analog signals, digital inputs, HMI screens, and more, configured exactly to your operation’s workflow. And they leave our facility labeled, documented, and ready for your inspector’s checkmark.

And yes, we challenge customer design files and BOMs when we see potential problems because we care about what happens after install day—not just hitting the ship date.

Non-UL Contract Manufacturing for Electro-Mechanical Assemblies

Many of our OEM clients don’t need UL labels—but they still demand consistent fabrication at IPC standards, with wiring harnesses, cable builds, box builds, and cleanroom-ready assemblies that perform like they were built in-house. That’s why they treat us like the extension of their own shop. And we design that way intentionally.

From simple junction boxes to full control systems, our contract manufacturing builds follow Class Three standards and benefit from an on-staff IPC-620 certified trainer. Semiconductor and cleanroom clients especially value this consistency—and the ability to scale production without compromising quality.

Get Started

Latest UL 508 Control Panels Posts

Making the world move through the flip of a switch is our passion, and we want the opportunity to quote your next project.

Get StartedOur Role as the OEM’s Quiet Partner

The most flattering compliment we hear from OEMs? “Our customers can’t tell if it was built at our facility or yours.”

That’s the goal. Prairie Electric isn’t chasing brand clout or labelling our name all over your products: we’re here to quietly amplify your capability. In fact, in industries where control panel designs are understandably proprietary, we go out of our way to ensure total confidentiality. Some industries consider their panel “secret sauce.” Others just need it to work, every day, no skipping a beat. Either way, we’re in your corner—and we stay out of your spotlight when you ask.

Where Custom Panels Make the Difference

Off-the-shelf control systems work great—until your process calls for something they weren’t built to handle. That’s where we come in. Prairie Electric specializes in custom control panel design/builds that adapt to your operation instead of forcing your operation to adapt to the panel.

Whether you’re operating high-output sugar conveyors, monitoring pumps in a wastewater facility, or cooling racks in a hyperscale data center, control is everything. Our custom-built panels help engineers dial-in repeatability, responsiveness, and integration at a level standardized systems can’t touch.

We build panels for process engineers, operation managers, and plant owners who want control over their process—and confidence to grow.

Industries We Serve

We’ve built panels for:

- Water & wastewater infrastructure

- Food & beverage processing lines

- Material handling & automated conveying

- Car wash OEMs and franchises

- Semiconductor & cleanroom systems

- Manufacturing, robotics, and packaging systems

- Data center support systems (cooling, sensing, monitoring)

And we’re actively expanding partnerships with:

- Conveyor system manufacturers looking for scalable 50–100+ panel build quantities

- OEMs who need short-run builds, prototypes, or duplicated systems

- Data centers and hyperscale campuses investing in custom power and cooling control solutions

Volume production helps us amortize engineering costs and improve pricing efficiency—you get reliable builds, faster support, and more leverage over future upgrades.

Our Process: Design, Fabricate, Test, Support

Your panel doesn’t start on the shop bench—it starts with a conversation. We work through drawings, flag issues early, and suggest enhancements that might save headaches (and overtime) down the road.

From there, our engineers draft schematics, select components, and prepare panel layouts that factor in thermal dissipation, accessibility, field wiring, and future expansion. We collaborate with your in-house engineering team—or serve as it, depending on your needs—and communicate constantly along the way.

Then, it’s into the shop, where our skilled technicians build every panel with pride and precision. We test it, label it legibly, document everything, and support it long after it hits your dock.

We don’t aim to be the biggest or the cheapest—we aim to be the ones you trust when your process depends on getting it right the first time.

Let’s Build Something That Works

Prairie Electric’s Control Panel Division is a certified UL 508 shop, but we’re a lot more than a label. We’re a group of engineers, builders, and integration partners who take ownership of what we build—and make life smoother for the customers who count on it.

Need thoughtful design? Clean manufacturing? High-volume repeatability? We’re ready.

Contact Prairie Electric today to collaborate on your next control panel project—and experience the confidence that comes from working with a quiet, capable extension of your production team.