When it comes to your home’s electrical wiring, safety is crucial. At Prairie Electric, we often get questions about aluminum wiring. In this guide, we’ll discuss the history of aluminum wiring, its safety concerns, and best practices for keeping it safe. If you’re wondering, “Is aluminum wiring safe?” or looking for ways to make it safer, we’ve got the answers.

The History of Aluminum Wiring

Aluminum wiring was commonly used in homes from the mid-1960s to the mid-1970s. At that time, copper was expensive and hard to find. Aluminum was a cheaper alternative. It conducts electricity well and is more flexible than copper. However, using aluminum wiring raised safety issues that we still talk about today. Older electrical devices often weren’t made for aluminum, which led to electrical fires. Thankfully, updated standards have improved the safety of aluminum wiring.

The National Electrical Manufacturers Association (NEMA) notes that while aluminum wiring became popular, it also led to complaints about connection failures. In response, the industry developed new standards and connectors to improve safety.

Aluminum Wiring for Service Conductors

It’s important to know the difference between aluminum wiring used for service conductors and wiring inside the house. Most homes use aluminum wiring from the service conductor, which brings electricity from the transformer to your home. This type is generally safe and commonly used in power lines.

Safety Concerns with Aluminum Wiring

The main safety issues arise from aluminum wiring inside homes, where it connects to outlets and switches. Here are the key concerns:

- Oxidation and Corrosion: Aluminum is more prone to oxidation than copper. When it oxidizes, it forms a layer that can make the wire less conductive and cause overheating, leading to fire risks.

- Expansion and Contraction: Aluminum expands and contracts more than copper with temperature changes. This can loosen connections over time, which may cause arcing and overheating.

- Compatibility Issues: Most outlets and switches are made for copper wiring. Using aluminum with non-compatible devices can lead to poor connections and increased fire risk.

How to Identify Aluminum Wiring

If you think you might have aluminum wiring, you can check a few things:

- Check the Wiring Casing: Look for labels on the wiring. Aluminum wiring will usually have “AL” or “Aluminum” marked on it.

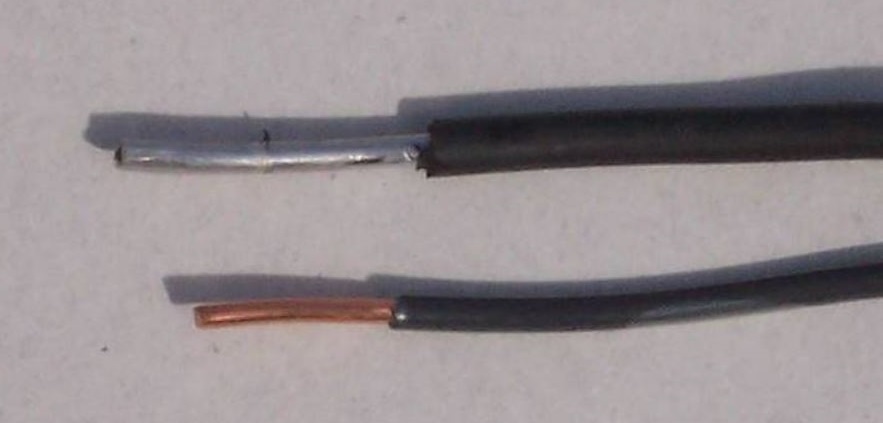

- Examine the Bare Wires: If you can see the wires, aluminum will look silver, while copper is reddish-brown.

Ensuring the Safety of Aluminum Wiring

If your home has aluminum wiring, follow these steps to keep it safe:

- Use Properly Rated Devices: Make sure all switches and outlets are rated for aluminum. Look for devices marked “CO/ALR,” which are designed for aluminum wiring.

- Pigtailing Aluminum to Copper: One safe method is to pigtail aluminum wires to copper wires using a special connector. This connects the aluminum wire to a short copper wire, which then connects to the device. This reduces fire risks but should only be done by a licensed electrician.

- Regular Inspections: Schedule regular electrical inspections with a licensed electrician. They can find potential problems with aluminum wiring and suggest repairs or upgrades.

The Importance of Hiring a Licensed Electrician

Hiring a licensed electrician is crucial when working with aluminum wiring. Here’s why:

1. Expertise and Knowledge

Licensed electricians have the training to handle aluminum wiring safely and know how to reduce risks.

2. Proper Tools and Materials

Professionals use the right tools and materials, like CO/ALR-rated devices, to ensure safe connections.

3. Compliance with Codes and Standards

They are familiar with local codes and will make sure your wiring meets safety standards.

4. Peace of Mind

A licensed electrician gives you peace of mind knowing your electrical system is safe.

When to Replace Aluminum Wiring

Sometimes, replacing aluminum wiring with copper may be the best option. Consider a full replacement if:

1. Extensive Remodeling

If you’re doing major renovations, it’s a good time to replace aluminum wiring for safety.

2. Persistent Issues

If you have ongoing problems like frequent breaker trips or warm outlets, replacement may be needed.

3. Peace of Mind

For homeowners who want to eliminate risks, replacing aluminum wiring with copper is a smart investment.

Aluminum wiring has its risks, but with the right precautions, it can be made safe. At Prairie Electric, we stress the importance of hiring a licensed electrician for any work involving aluminum wiring. Whether you need to replace or add an outlet, professional help is essential. Regular inspections, using the right devices, and pigtailing or replacing aluminum wiring can keep your home safe.

If you have concerns about aluminum wiring in your home, contact Prairie Electric. Our experienced electricians are ready to help ensure the safety and reliability of your electrical system.