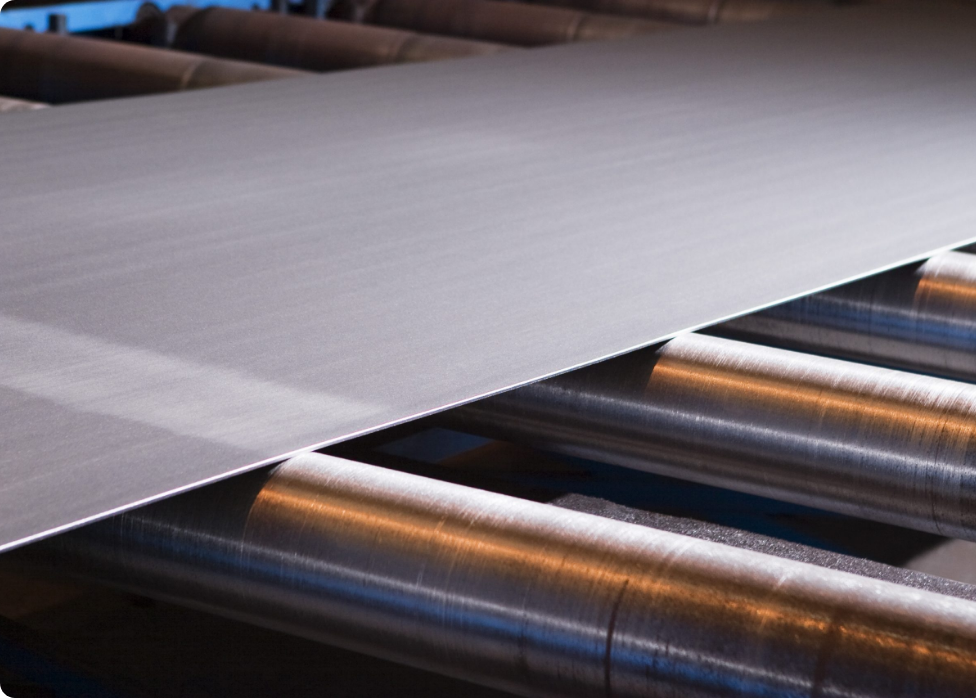

Automated Conveyor Systems

Prairie Electric specializes in electrical, assembly, and programming services for automated conveyor systems, delivering customized solutions for warehousing, production, and industrial needs with in-house UL-listed standards.

Prairie Electric performs electrical, assembly, and programming services for businesses reliant upon automated conveyor systems.

Our expertise extends to creating and programming systems that enable efficient product sorting, labeling, and much more.

In addition to conveyor systems, we design and implement programmable solutions for peripheral technologies such as robotic arms and automated bottling systems.

We specialize in building advanced automation systems that include various types of conveyors, such as:

- Belt conveyors

- Screw conveyors

- Chain conveyors

- Vibrating conveyors

- Pneumatic conveyors

Leveraging cutting-edge technology and our extensive experience, we deliver tailored solutions to meet the unique needs of your warehouse, production, or industrial operations.

Get Started

Making the world move through the flip of a switch is our passion, and we want the opportunity to quote your next project.

Get StartedProven Processes for Successful Systems

Our approach to building automated conveyor systems follows a structured three-step process, ensuring we meet both your technical and operational requirements.

- Design: We begin by understanding the system’s goals and lifecycle. We then focus on how our work will integrate seamlessly into your overall system requirements.

- Review: We conduct a thorough review to verify that the design meets your specifications and expectations.

- Implementation: Our team executes the design, followed by application evaluations to assess system performance and productivity.

Scalable Solutions

Our scalable solutions can be applied to any automated conveyor system. We provide fully automated systems with electrical controls that are designed and built in-house.

When you partner with Prairie Electric, you gain access to world-class electrical design services and manufacturing capabilities. Our state-of-the-art prefabrication shop enables us to design and assemble electrical panels to meet your system’s needs.

We adhere to UL-listed standards for all of our work. Additionally, our in-house team handles the fabrication, testing, and quality control of every component, ensuring high standards of reliability.

Comprehensive Conveyor System Components

Our services extend beyond conveyor systems. We also provide essential components such as:

- Photo eyes

- Limit and proximity controls

- PLCs (programmable logic controllers)

- Other vital processing equipment

With Prairie Electric, you can trust that your automated conveyor system will be equipped with the latest technology and designed to improve your operations.