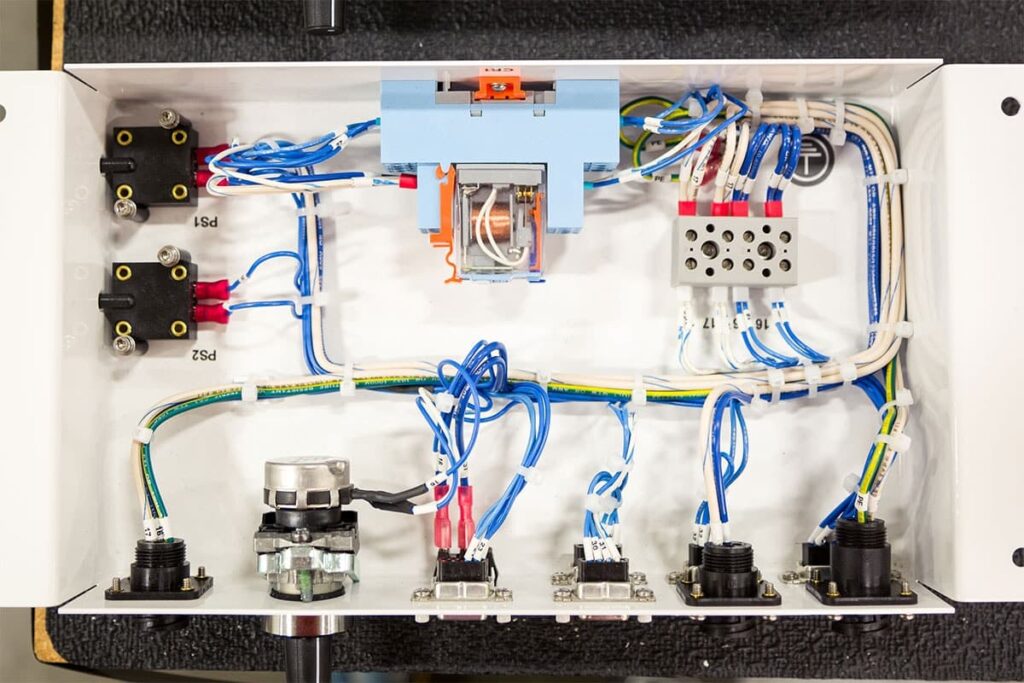

Electricity is essential. Not only is it required in our homes, offices, restaurants and hospitals, but it plays an integral role in industrial facilities, ranging from manufacturing plants to water purification facilities and everything in between. Electricity must be channeled and controlled for safety and functionality – that’s where an industrial electrical panel comes in.

What is an industrial electrical panel?

Simply put, you can think of an industrial electrical panel comparable to your home’s breaker box. It serves a similar purpose. However, it’s not quite the same thing, and in electrical panel shop, special steps must be taken to ensure that all Art. 409 codes and requirements are followed for safety, security and protection.

First, the panel must be built to the correct specifications – it needs to be of the right type, of the right size, and located in the appropriate place to meet Art. 409 requirements. These will vary from panel to panel depending on the specific use of the panel, the connection types and more.

While some industrial electrical panel designs are ubiquitous, some needs are more complex. This requires custom electrical panel building and design, also called supplier engineering. In this instance, you (the client) will work with a supplier to design not only the industrial electrical panel, but the wiring and layout within the facility. For instance, this would include everything from the swing of the cabinet doors to the number of electrical outlets per circuit and more.

Electrical Panel Considerations:

Other considerations that must be made when designing and building an industrial electrical panel in a panel shop include the ambient temperature in the area where the device will be located. If the temperature will be high, such as near a process area, then the panel may require a ventilation fan to maintain temperature, or even air conditioning within the panel cabinet in some instances. These bring with them the need for additional maintenance, from cleaning fan blades to cleaning AC filters periodically.

An industrial electrical panel should include optimum overcurrent protection, the right short circuit current rating, the correct ampacity for supply conductors, proper grounding and good workmanship. Failing to meet these requirements will mean that your panel does not comply with Art. 409 requirements, but that it may also pose a significant safety risk to personnel within your facility.

Electrical Panel Shop Services and Products:

Panel shops offer some of the best ways to customize exact operations the way you need for your industrial space or business. Control panels are built to fit the operational requirements for virtually any industry, including hydraulics, HVAC, medical, refrigeration — you name it. An electrical panel shop can vastly improve the efficiency of everyday industry processes through automation. Depending on the type of operations that must be programmed, control panels can automate a host of actions and tasks, including:

- Elevator operations

- Amusement park rides

- Outdoor water features

- Assembly lines

- Heating/cooling systems

- Building security operations

Why choose our Prairie Electric panel shop?

Prairie Electric offers a UL® 508 authorized panel shop. This means that we have received an Underwriter Lab Safety certification and must meet high standards that address safety, quality and customer service. There are a lot of benefits to working with an electrical manufacturer that has a UL® 508 authorized panel shop:

- Competition’s got nothing on us: We can cut through expensive delays caused by red tape by removing red-tagged panels at the building. In addition, our technicians undergo UL-hosted trainings and workshops to ensure they are highly knowledgeable and up-to-date on panel shop technologies.

- Strict adherence to building codes: To become certified, a panel shop must meet high manufacturing standards, including wiring protection, safe component usage, and compliance with NEC and CEC requirements.

- Flexibility with component sourcing: Due to an agreement between UL and CSA International, customers who choose a UL-certified shop have more freedom when sourcing components. Previously specified CSA components can be used in UL panels.

Electrical panel shop services and products:

On top of Prairie’s UL certification, here’s a quick list – but by no means exhaustive – of the panel-related services and products we offer:

- Complete turnkey system integration

- PLC, HMI, & PC Based Control Systems

- Continued support throughout industrial panel life:

- 24-hour repair service

- System maintenance and troubleshooting

- Panel manufacturing

- Retrofitting

Our experienced technicians will be there to work on every step of the electrical panel-building process, starting from design, to installation and technical support. Prairie electricians can also work with your OEM facility build control systems throughout the design process to ensure seamless integration.

Looking to improve system operations for your industrial space or business? Prairie Electric has over 30 years of experience in electrical contracting services in Pacific Northwest. Contact us today and speak with a knowledgeable electrician about our panel shop and services we provide.